Construction case of photovoltaic system

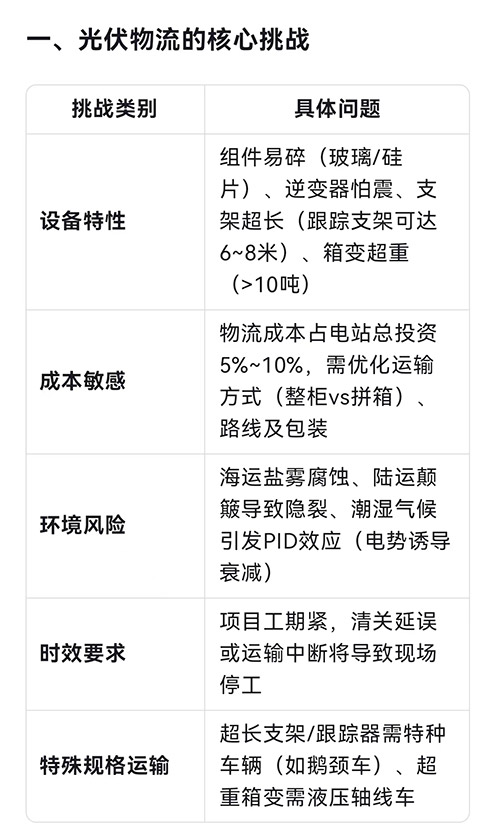

Photovoltaic system logistics is a key link in the construction of photovoltaic power plants, involving global supply chain management, transportation scheme design, and on-site distribution of large-scale/precision equipment such as non-standard components, brackets, inverters, and transformers. The core challenge lies in balancing cost efficiency and equipment safety (shatterproof, moisture-proof, shock resistant) in logistics, while also addressing the special transportation needs of ultra large components such as tracking brackets and box transformers. The following are the core points and solutions for photovoltaic logistics:

Case study of successful delivery of logistics for wind and solar complementary integrated wind power main body by CGN

From project initiation, bidding, follow-up, scheme evaluation, cost target, operation, to lengthy waiting, spanning 3 years. Finally, from October 21 to November 3, 2023, the main body of the wind duct was successfully assembled. After 11 days, it marks the completion of the first wind turbine hoisting for the 1 million kilowatt wind power project of CGN Xinjiang Ruoqiang, and the rapid production of the wind turbine from the factory production line for one month.

Project nature: The CGN Ruoqiang 1 million kilowatt wind power project is located in Ruoqiang County, Bayingolin Mongol Autonomous Prefecture. The site is divided into two plots, east and west, with a total coverage area of about 176 square kilometers and a total of 141 wind turbines. It is equipped with a 100000 kilowatt/200000 kilowatt hour energy storage project, two new 220kV collection stations, and a 220kV transmission line project.

Project Introduction: This project was successfully included in the list of the first batch of market-oriented grid connected new energy projects in Xinjiang Uygur Autonomous Region in 2023 on July 4th. Due to geological reasons such as being located in saline alkali swamps, it poses great challenges to project construction, equipment transportation, and installation. To this end, the project construction personnel completed the first wind turbine foundation pouring on September 12th through measures such as precipitation, stone replacement, and optimization of the construction design plan. Currently, all on-site construction work has been carried out.

Logistics participation process:

Front end outsourcing factory fan head loading:

中段套筒装载示意场景图:(主筒)

Scene diagram of lifting the main body of the cylinder (schematic diagram of cylinder splicing)

Core stages of logistics participation: front-end bidding cost estimation, overall pre review, consortium development, integration and distribution collaboration, supply chain outsourcing testing, static pain point display, road survey, risk control details control, dynamic pain point risk control, one-stop full scenario participation. Large non-standard one-stop supply chain assistance to solve core pain points. The main party, the first party, and the outsourcing party have made every effort to cooperate with our company in responding from the front end to the end, using the optimal cost method to eliminate pain points, not only ensuring smooth delivery of the project schedule but also minimizing the overall project cost. Suppliers at every stage of the supply chain provide original delivery plans in response to logistics, maximizing cost compression. (Based on on-site fire access review, objective on-site conditions staggered matching, delivery according to return season, and sequential lifting of goods upon arrival, dynamic logistics and lifting costs are utilized to maximize space costs, and each link is coordinated to avoid time and space delays and repetition.)

The construction is currently in the wind season of Lop Nur, and the lifting difficulty of the project construction is relatively high. In order to carry out the lifting operation of the wind turbine, the Nanjiang Base Company has conducted multiple verifications of the lifting plan, strengthened on-site supervision and meteorological environment monitoring, closely monitored the safe operation window period, and ensured the safe and efficient completion of the first wind turbine lifting, accumulating valuable experience for subsequent wind turbine lifting.

Core stages of logistics participation: front-end bidding cost estimation, overall pre review, consortium development, integration and distribution collaboration, supply chain outsourcing testing, static pain point display, road survey, risk control details control, dynamic pain point risk control, one-stop full scenario participation. Large non-standard one-stop supply chain assistance to solve core pain points.

The main party, the first party, and the outsourcing party have made every effort to cooperate with our company in responding from the front end to the end, using the optimal cost method to eliminate pain points, not only ensuring smooth delivery of the project schedule but also minimizing the overall project cost. Suppliers at every stage of the supply chain provide original delivery plans in response to logistics, maximizing cost compression. (Based on on-site fire access review, objective on-site conditions staggered matching, delivery according to return season, and sequential lifting of goods upon arrival, dynamic logistics and lifting costs are utilized to maximize space costs, and each link is coordinated to avoid time and space delays and repetition.)

The construction is currently in the wind season of Lop Nur, and the lifting difficulty of the project construction is relatively high. In order to carry out the lifting operation of the wind turbine, the Nanjiang Base Company has conducted multiple verifications of the lifting plan, strengthened on-site supervision and meteorological environment monitoring, closely monitored the safe operation window period, and ensured the safe and efficient completion of the first wind turbine lifting, accumulating valuable experience for subsequent wind turbine lifting.