Deep Energy Yangxi Energy Storage Hoisting Project

Deep Energy Yangxi Energy Storage Hoisting Solution: Phase I 550MW Energy Storage Project of Deep Energy Yangxi Coastal Photovoltaic-Storage Integration Project

Longxiang Logistics executed the hoisting operations for Phase I 550MW energy storage project of Deep Energy Yangxi Coastal Photovoltaic-Storage Integration Project. We balanced crane models based on equipment arrival sequence, optimizing performance under site conditions, and arranged construction procedures according to equipment delivery schedules as detailed below.

Hoisting Techniques:

The construction site features flat terrain with completed foundations for energy storage containers and EPS containers, and backfilled/compacted cable trenches meeting hoisting conditions. One working face will be utilized following this sequence: hoisting from southwest to northeast corner in groups, with transport vehicles entering from northeast corner, reversing into 10m-wide access roads between foundation groups, and exiting forward from northeast corner after completion.

Hoisting Plan: Our field technicians conducted site survey revealing the plant area measures 65m×32m with only one narrow access road available for crane setup - creating significant operational constraints at this fire lane endpoint.

With 32m distance from diameter to farthest construction point, objective environmental limitations necessitated using over 450-ton cranes. Cost optimization was achieved through initial 2-day 450-ton crane operations for first batch delivery, followed by 200-ton cranes for subsequent batches.

Hoisting Methodology:

Materials transported to site via roll-on/roll-off vehicles, with crane positioned at mid-range for boom deployment using lifting rings/hooks for vertical adjustments. Limited space required coordinated operations between 260-ton and 220-ton cranes over minimum 2-day period. Single entry/exit routes necessitated multiple repositioning maneuvers. Elevated operations employed bottom-supported longitudinal cross-operations for long-distance relocation and short-range hoisting.

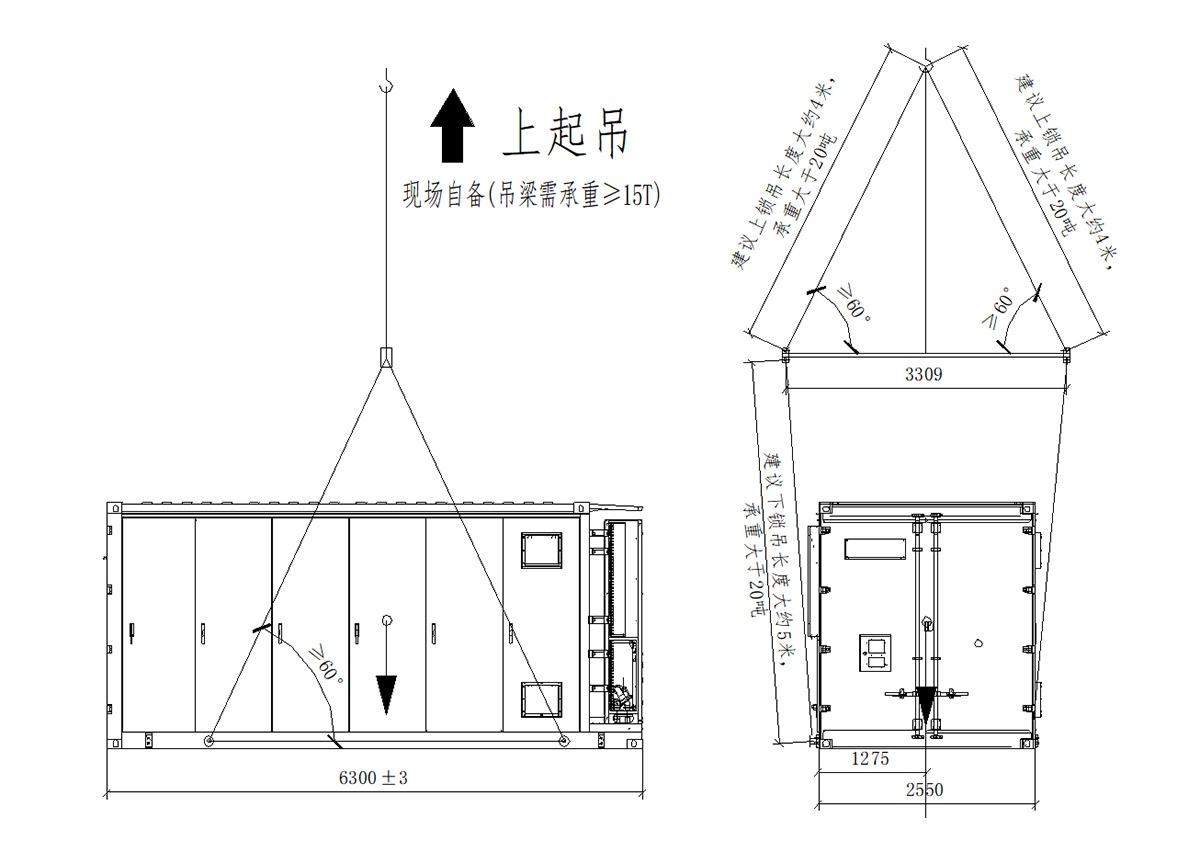

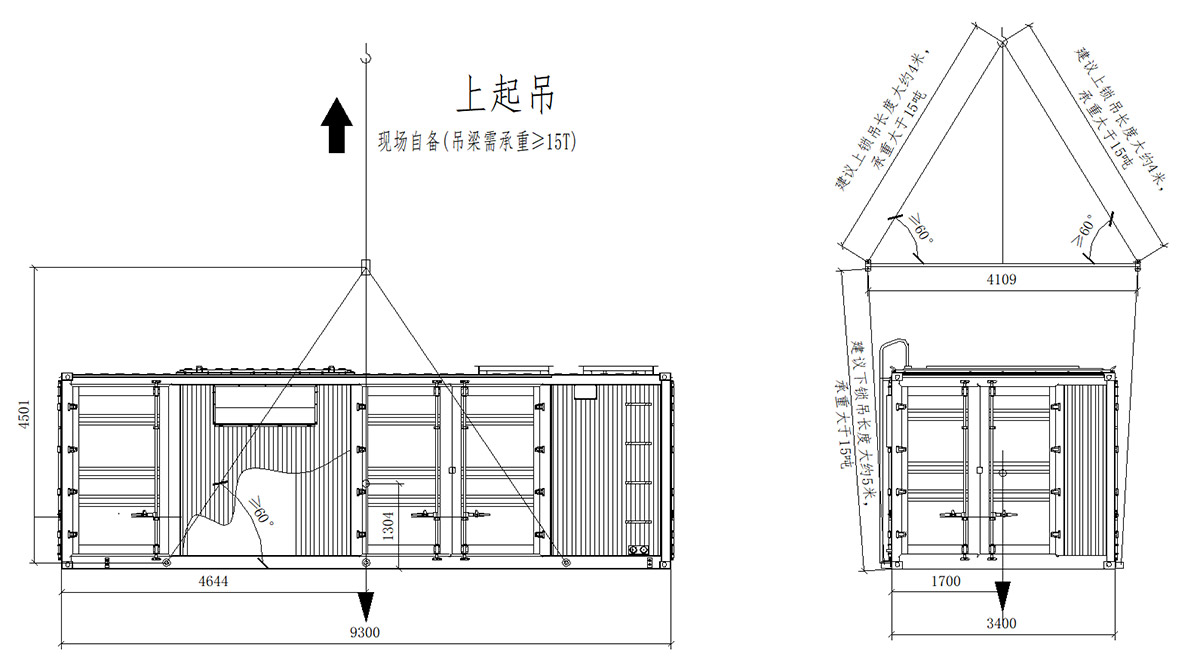

Hoisting Precision: Specialized balance techniques using adjustable spreader bars according to container dimensions

Lightweight Rigging

Weight-specific rigging configurations

60-70 Ton Rigging

Full process documentation including video records, acceptance documents, and tripartite inspection reports. Refined process design with digital monitoring ensures safe/efficient execution of heavy hoisting operations in complex environments.

Applicable to heavy equipment (100+ ton) project management in energy, chemical, and infrastructure sectors. Technical specifications require adjustment based on project-specific parameters.